Produits phares

Method and system for processing slag material Google

US10799882B2 Method and system for processing slag material Google Patents A method and system is used to process slag material to yield by-products including a

Contact

Generation of iron and steel slag : NIPPON SLAG

Process that generates iron and steel slag Iron and steel slag can be broadly classified into blast furnace slag that is generated when iron ore is melted and reduced in a blast furnace, and steelmaking slag that is generated during the steelmaking

Contact

Making Slag an overview ScienceDirect Topics

Apr 05, 2010In this study, the slag was processed by microwave application, in order to utilize the TiO 2 containing phase. Heating of the slag was performed in 2.45GHz microwave (MW) applicator. It was observed that sudden increase of the specimen temperature or thermal runaway (TRW) occurred, and a part of the specimen melted.

Contact

US9217185B2 Method of reduction processing of steel

The method of reduction processing of steel-making slag, includes: a hot steel-making slag inflow process of continuously or intermittently charging, from a slag supplying container, hot steel-making slag to a molten slag layer on a molten iron contained in an electric furnace while adjusting an amount of inflow with the slag supplying container; a reducing agent supplying process of supplying

Contact

Processing and reusing technologies for steelmaking slag

Iron is separated after the slag is cooled and crushed through means of magnetic separation (Horii et al., 2013). This constitutes part of the by-products used in this research. Recycling of...

Contact

Processing of Non-Ferrous Metallurgy Waste Slag for its Complex

Dec 10, 2021高达10%返现The elemental iron and carbon contained in the clinker function as energy reagents in the liquid phase, which, when interacting with oxygen, release the heat necessary for smelting. In the presence of clinker, the Cu content in the slag decreases, and Zn

Contact

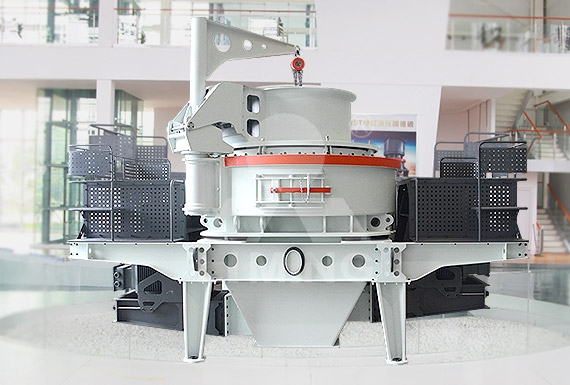

The Six Main Steps of Iron Ore Processing Multotec

Mar 14, 2018Six steps to process iron ore 1. Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for

Contact

The Step-by-Step Process of Producing Iron from Iron Ore

Oct 23, 2017Now, this carbon monoxide that is unstable, reacts with the ore to form carbon dioxide and iron. The Separation Of Iron- The molten iron that settles down at the bottom of the furnace contains impurities and rocks that combine with the

Contact

Gold Processing Methods Iron Slag Industris Mining company

Iron Slag With Gold. gold processing methods iron slag jumpingcastlejhb. gold processing methods iron slagSorting Msw Municipal Waste Management Process Machine Buy .Sorting Msw Municipal Waste Management Process Machine Find Complete recycled asphalt concrete slag coal. Antique Slag. A Poor Mans Method Of Smelting Gold Sciencing

Contact

Basics of slag production Article on the slag industry Global Slag

Oct 27, 2011BOS Slag. Process. When molten iron (referred to as “hot metal”) from the blast furnace is to be converted into steel, the main tasks are the removal of carbon, silicon and phosphorus. The LD (Linz-Donawitz) process is by far the most widely used,

Contact

processing methods iron slag

Gold Processing Methods Iron Slag. gold processing methods iron slag offers 1255 electric furnace for bricks products. About 75 of these are refractory, 3 a Get price

Contact

Method of processing slag russianpatents

The invention relates to metallurgy and can be used in the processing of metallurgical slags. Known methods of slag processing, including crushing, separation into fractions, pneumatic classification and magnetic separation products crushing and screening [1, 2]. Signs consistent with features of the invention is a method of processing slag

Contact

iron processing Britannica

iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties. It constitutes 5 percent by weight of the Earth’s crust, and it is the

Contact

METHODS AND SYSTEMS FOR RECOVERING PRODUCTS FROM IRON AND STEEL SLAG

Systems and methods for processing slag produced by iron and steel making processes are disclosed. The slag is treated produce a series of valued industrial products, such as metal oxides, metal carbonates, rare-earth metals, and water glass. The systems and methods also integrate slag processing with CO 2 sequestration and flue gas

Contact

Iron and Steel Slag Statistics and Information USGS.gov

Depending on the cooling method, three types of iron slag are produced— air cooled, expanded, and granulated— that have different types of applications. Subscribe to receive an email notification when a new publication is added to this page. On the Questions tab of the subscriber preferences page, select "Iron and Steel Slag" and any other

Contact

processing methods iron slag

Gold Processing Methods Iron Slag scuderiengine.de 2021-4-29 Gold Processing Methods Iron Slag. Quantitative analysis of gold concentrate ,gold is a chemical element in the periodic table that has the sym-bol Au with an atomi. get price

Contact

Processing Metallurgical Slag Mecchi, Anton

Aug 28, 20061. A method of processing a starting material in the form of waste raw metallurgical slag having a heavy metal content which is undesirable, and to dispose of the raw slag while producing at least one valuable product, the method being characterised in that it includes the steps of: admixing a raw slag which comprises a mixture of at least one manganese-containing slag and at least one iron

Contact

The Six Main Steps of Iron Ore Processing Multotec Canada

Mar 14, 2018Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Contact

Slag Wikipedia

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-products of recovering non-ferrous materials like copper, nickel, zinc and phosphorus). Within these general categories, slags can be further categorized by

Contact

METHOD FOR SCREENING IRON STEEL SLAG, METHOD FOR R

专利名称:method for screening iron steel slag, method for recycling iron steel slag. and method for manufacturing raw. material for iron making. 发明人:takagi yuki, 高 木 勇輝,ishida. tadahira,石田 匡平,nishina yoshiaki,西名. 慶晃,maeda takahiko,前田 孝彦,nihei. masamitsu,二瓶 真光,kyozuka. toshikatsu,経

Contact

Processing of Non-Ferrous Metallurgy Waste Slag for its

Dec 10, 2021The article presents an overview of the methods of processing slag from Waelz process, and various approaches employed by scientists globally, aimed at processing such slags. by the method of complex processing as iron-containing additive in the production of Portland cement clinker [60,61,62,63]. The chemical composition of Waelz slag in

Contact

Cold crystallization kinetics of slag from the joint smelting of

Jun 24, 2022The cold crystallization kinetics of the glass-crystal composition (90.3 vol% of glass) made of slag from the joint smelting of oxidized nickel and sulfide copper ores were studied in the temperature range from 876 to 1003 °C with a heating rate of 5–20 °Cmin–1 in an inert atmosphere (the elemental composition of slag is mass%: 0.09 Ni, 0.12 Cu, 0.02 Co, 0.2 Zn, 15.7 Fe, 0.2 S, 50.0

Contact

processing methods iron slag_Small Mobile Crushing Machine In

gold processing methods iron slag Iron and steel slag refers to the type of metal manufacturing slag that is generated during the process of manufacturing iron and steel products. The term "slag" originally referred to slag produced by metal manufacturing processes, however it is now also used to describe slag that originates from molten waste

Contact

Gold Processing Methods Iron Slag

Iron Smelter Slag Crushing Methods thai-physio.de. Iron Smelter Slag Crushing Methods. The iron is then drained from the bottom of the furnace into a mould and allowed to harden 16 the blast furnace remains the principal method of smelting iron to this day 14 there is a tradeoff for this speed however melting the iron causes it to take on a

Contact

Method of processing slag russianpatents

The invention relates to metallurgy and can be used in the processing of metallurgical slags. Known methods of slag processing, including crushing, separation into fractions, pneumatic classification and magnetic separation products crushing and screening [1, 2]. Signs consistent with features of the invention is a method of processing slag

Contact

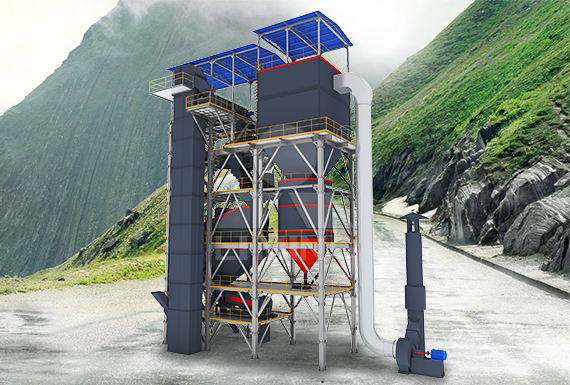

IRON AND STEEL SLAG USGS

the remainder of sales. Slag was processed by 28 companies servicing active iron and steel facilities or reprocessing old slag piles at about 124 processing plants (including some iron and steel plants with more than one slag-processing facility) in 33 States, including facilities that import and grind unground slag to sell as ground granulated

Contact

Processing of Non-Ferrous Metallurgy Waste Slag for its

Dec 10, 2021The article presents an overview of the methods of processing slag from Waelz process, and various approaches employed by scientists globally, aimed at processing such slags. by the method of complex processing as iron-containing additive in the production of Portland cement clinker [60,61,62,63]. The chemical composition of Waelz slag in

Contact

The Six Main Steps of Iron Ore Processing Multotec Canada

Mar 14, 2018Six steps to process iron ore. 1. Screening. We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage. A static screen is used to divert the fine particles for crushing. This step prevents overloading the crusher and increases its efficiency.

Contact

Processing Metallurgical Slag Mecchi, Anton

Aug 28, 20061. A method of processing a starting material in the form of waste raw metallurgical slag having a heavy metal content which is undesirable, and to dispose of the raw slag while producing at least one valuable product, the method being characterised in that it includes the steps of: admixing a raw slag which comprises a mixture of at least one manganese-containing slag and at least one iron

Contact

Slag recycling Recovery Worldwide

Two main production methods are involved (Fig. 1). In the iron ore-based process, pig iron is produced from oxidic iron ores in a blast furnace. In an LD oxygen converter the molten pig iron is then processed together with steel scrap into crude steel. The use of iron and steel slag has a long tradition in Japan [4]. However, the produced

Contact

Steel Slag an overview ScienceDirect Topics

In the primary process, crude steel is produced in two ways. In the first method, the iron is produced from ore in the BF, thus, generating BF slag (BFS). BBOF slag (BOFS) is produced in the steelmaking process by using the molten iron coming from the BF. In the second method, slags are generated in the scrap-based steel industry.

Contact

Method of reduction processing of steel-making slag

The invention claimed is: 1. A method of reduction processing of steel-making slag, including: a hot steel-making slag inflow process of continuously or intermittently charging, from a slag supplying container, hot steel-making slag to a molten slag layer on a molten iron contained in an electric furnace while adjusting an amount of inflow with the slag supplying container; a reducing agent

Contact

Slag Wikipedia

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-products of recovering non-ferrous materials like copper, nickel, zinc and phosphorus). Within these general categories, slags can be further categorized by

Contact

TENORM: Copper Mining and Production Wastes US EPA

Jun 07, 2021Mining and Processing Methods. One layer is a waste containing iron and silica compounds and is discarded as slag slagByproduct left after a desired metal is thermally separated from its raw ore.. Approximately 75 percent of the copper concentrate ends up as slag. The other layer, called "matte copper," consists of copper, iron sulfide and

Contact

METHOD FOR SCREENING IRON STEEL SLAG, METHOD FOR R

专利名称:method for screening iron steel slag, method for recycling iron steel slag. and method for manufacturing raw. material for iron making. 发明人:takagi yuki, 高 木 勇輝,ishida. tadahira,石田 匡平,nishina yoshiaki,西名. 慶晃,maeda takahiko,前田 孝彦,nihei. masamitsu,二瓶 真光,kyozuka. toshikatsu,経

Contact

processing methods iron slag

Gold Processing Methods Iron Slag. gold processing methods iron slag offers 1255 electric furnace for bricks products. About 75 of these are refractory, 3 a Get price

Contact

Cold crystallization kinetics of slag from the joint smelting of

Jun 24, 2022The cold crystallization kinetics of the glass-crystal composition (90.3 vol% of glass) made of slag from the joint smelting of oxidized nickel and sulfide copper ores were studied in the temperature range from 876 to 1003 °C with a heating rate of 5–20 °Cmin–1 in an inert atmosphere (the elemental composition of slag is mass%: 0.09 Ni, 0.12 Cu, 0.02 Co, 0.2 Zn, 15.7 Fe, 0.2 S, 50.0

Contact