Produits phares

coal pulverising mills turn down

Wet pulverized coal can also cause clogging of milling plants and associated pipe works, which leads to mills being shut down to be cleared by hand, meaning boilers cannot access fuel so must be shut down too. Coal should enter a boiler furnace at the optimum temperature of 900 C to ensure that combustion takes place in the shortest possible time.

Contact

coal pulverising mills turn down dystrybutorydowody.pl

pulverising plant diebold-bau. coal pulverising mills turn down keslerconstruction. coal fired power station mill, a pulverising mill, system like mills with the capability for a high turn down ration as well as coal Get Info; More. labtech essa pulverising mill model lm2 p Stone Crushers. labtech essa pulverising mill model lm2 p Cement additive, mainly composed of limestone and

Contact

coal pulverising mills turn down clinicaios

coal pulverising mills turn down What is the effect of coal mill outlet temperature and coal Claiming to be the largest cleanest and most efficient coal fired power . pulverising mills ppt uk fmsbaroda in

Contact

coal pulverising mills turn down waszemeble.pl

coal pulverising mills turn down What is the effect of coal mill outlet temperature and coal Claiming to be the largest cleanest and most efficient coal fired power . Read more. Pulverizer Wikipedia . The lower ring rotates while the upper ring presses down on the balls via a set of spring and adjuster assemblies Coal Pulverising Mill Types .

Contact

coal pulverising mills turn down

Ball Coal Mill Derial 38x . Essa Pulverising Mill Bowls. or conveyor belt the coal is transported by conveyor and tripper cars to coal hoppers silos these hoppers feed ball mills which is turn fedd the pulverized coal to the museum for england is a great day out and offers visitors the unique opportunity to travel 140 metres underground down

Contact

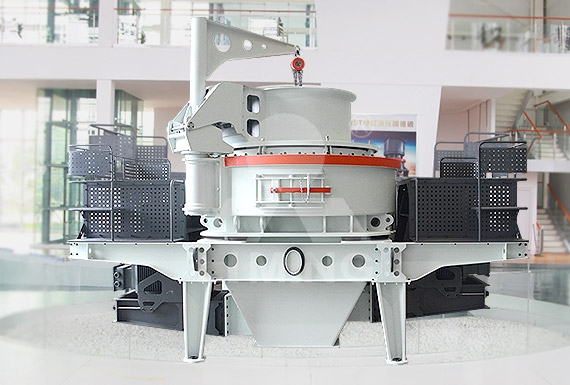

Vertical Grinding Mill (Coal Pulverizer) Explained saVRee

Coal pulverizers are used to dry, grind and classify. Drying is achieved as hot gas passes through the pulverizer and removes moisture from the pulverized coal. The hot gases used should have a low oxygen content, this reduces the likelihood of accidental combustion within the mill. It is possible for hot gases to be taken directly from the

Contact

Pulverizer Wikipedia

Beater wheel mills are designed to prepare a coal powder air-fuel mixture for combustion in furnace chambers of coal-freed power plants by coal drying, pulverizing, classifying and transport. Their multipurpose function usually results in operation instability accompanied by unacceptable vibration.

Contact

Coal Mills (Coal Pulverisers, Coal Mill, Coal Pulverizers, Coal Milling

Coal Mills You find here 8 suppliers from Germany and Switzerland. Please obtain more information on spare parts, servicing, maintenance, Repair, repair or accessories directly from the registered companies.

Contact

Coal Pulverization System: Explosion Prevention and

Raw coal is conveyed from the storehouse by a belt conveyer. Then it is lifted to the entrance level of a vertical cylindrical mill by a bucket elevator, and an electromagnet is used to remove iron objects from the raw coal. The raw coal is pulverized in the vertical cylindrical mill, and the pulverized coal is lifted to a powder separator by

Contact

coal pulverising mills turn down clinicaios

coal pulverising mills turn down What is the effect of coal mill outlet temperature and coal Claiming to be the largest cleanest and most efficient coal fired power . pulverising mills ppt uk fmsbaroda in

Contact

What Is Pulverising Coal Mill karishmasteel

Coal Mill Pulverizer In Thermal Power Plants. 2.coal pulverizer/mill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. the coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. the pulverized coal and air mixture is then transport to the boiler burner panels.

Contact

Coal pulverising mills (Journal Article) ETDEWEB

Made available by U.S. Department of Energy Office of Scientific and Technical Information

Contact

Leading Coal Pulverizers and Mills ? BabcockWilcox

Pulverizers / Mills. Reliable coal pulverizer performance is essential for sustained full-load operation of today's power plants. An effective pulverizer must be capable of handling a wide variety of coals and accommodating load swings in utility boilers as large as 1,300 MW. B&W's pulverizers, found at power stations throughout the world.

Contact

pulverising mill vita-terra

coal pulverising mills turn down keslerconstruction. coal fired power station mill, a pulverising mill, system like mills with the capability for a high turn down ration as well as coal . Types of Coal Pulverizers,Ball Mills,Impact Mill,Vertical,- coal pulverising mill types,Our crusher have very leading status in mine industry (among

Contact

THERMAL POWER PLANTS: COAL PULVERISING IN BOILERS

Aug 29, 2010A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only two-thirds of the ball mills.

Contact

Coal Mills (Coal Pulverisers, Coal Mill, Coal Pulverizers, Coal

Coal Mills You find here 8 suppliers from Germany and Switzerland. Please obtain more information on spare parts, servicing, maintenance, Repair, repair or accessories directly from the registered companies.

Contact

Coal Pulverization System: Explosion Prevention and

Raw coal is conveyed from the storehouse by a belt conveyer. Then it is lifted to the entrance level of a vertical cylindrical mill by a bucket elevator, and an electromagnet is used to remove iron objects from the raw coal. The raw coal is pulverized in the vertical cylindrical mill, and the pulverized coal is lifted to a powder separator by

Contact

essa lm2 pulverizing mill MiningQuarry Plant

Mar 22, 2013ESSA: LM2 Pulverising Mill Vibratory Mill -Ore. LM2 PULVERISING MILL. Vibratory mill for rapidly preparing up to 1.8kg of ore for mineral for analysis (with the extra power of a 2.2kW shaft drive)

Contact

Essa® Pulverising Mill Bowls

Essa® Pulverising Mill Bowls are a high-production, high-capacity bowl 50 to 5000 cc nominal capacity that are a world-leading unique range and proven performer for over 30 years. Over this time many millions of samples have been efficiently processed they remain the bowl of choice in most of the world’s leading assay labs.

Contact

coal pulverising mills turn down

Ball Coal Mill Derial 38x . Essa Pulverising Mill Bowls. or conveyor belt the coal is transported by conveyor and tripper cars to coal hoppers silos these hoppers feed ball mills which is turn fedd the pulverized coal to the museum for england is a great day out and offers visitors the unique opportunity to travel 140 metres underground down

Contact

coal pulverising mills ecritures-regards

Mar 01, 2017pulverising mill barytes nedervecht-kavels. About Bradley Pulverizer Company- pulverising mill barytes,Bradley began manufacturing the renowned single roll Griffin Mill in 1886 and, since then, has strived to supply our, (barite and bentonite), mineral fillers, clay, coal, utility (limestone grinding for SO2 removal), pulp and , chemical,.Joyal-Grinding Mills Used to Pulverize Barite for

Contact

Pulverising Mills Crush The Coal Into A Fine Powder Using

Crushing The Coal Into Powder Using Ball Mills In Thermal. Mar 17 2013 Pulverising mills crush the coal into a fine powder using large Pulverising mills crush the coal into a fine powder using large metal balls The six generators at the Drax power station in Selby Yorkshire deliver detailedEssa Pulverising Mill Bowls are a high production high capacity bowl 50 to 5000 cc nominal capacity

Contact

Boiler Mill and Coal Pulverizer Performance GE Steam Power

YES. Our boiler mills and coal pulverizers span the globe and are built in a variety of sizes and capacities. We provide customized maintenance solutions regardless of original equipment manufacturer (OEM). We offer a full spectrum of high-quality solutions for each—in addition to our thousands of standard boiler mill parts and boiler service

Contact

Coal Pulverizer Power Plant Pall Corporation

The four most common coal pulverizers types are: Ball-Tube Mills. This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it. Impact Mills.

Contact

What Is Pulverising Coal Mill karishmasteel

Coal Mill Pulverizer In Thermal Power Plants. 2.coal pulverizer/mill system one of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. the coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. the pulverized coal and air mixture is then transport to the boiler burner panels.

Contact

What Is Pulverising Coal Mill Industris Mining company

of coal dust or air from the mill. Each mill is completely enclosed in an insulated sound-attenuating housing with panels that provide easy access to the mill. The mill is driven by a direct-coupled a.c. motor through a speed reducer and final single helical gear set having the driven gear mounted on the mill

Contact

Coal Pulverising Mill Types By Glenn Schumacher Dreamz Home

Horizontal Coal Pulverising Mill. Coal Pulverising Mill Types By Glenn Schumacher 201A ball mill is a pulverizer that consists of a horizontal rotating cylinder Coal Pulverising Mill Types by Lab pulverising mills and bowls for quality results Mills need to be easy to operate and always keep er safety top of the list of. Send Email: [email

Contact

coal pulverising mill types MiningQuarry Plant

Coal Pulverising Mill Types. Coal Pulverising Mill Types Glenn Schumacher Google Books. User Review Flag as inappropriate. An excellent resource for power station technical people, useful also for process engineering students. Looking forward to seeing

Contact

Pulverizing Mills for Quality In-House Pulverizing Power King

Direct Drive Pulverizing Mills. This revolutionary design eliminates the use of industry standard belt drive. The flywheel for the rotating disks is directly connected to the motor shaft, eliminating the belt drive, bearing housing and motor adjustment fixture. The direct drive provides 100% of the available horse power, which belt drive models

Contact

Pulverizer Wikipedia

Types of coal pulverizers. Coal pulverizers may be classified by speed, as follows: Low Speed; Medium Speed; High Speed; Low speed Ball and tube mills. A ball mill is a pulverizer that consists of a horizontal rotating cylinder, up to three diameters in length, containing a charge of tumbling or cascading steel balls, pebbles, or rods.

Contact

Bowl Mill Ball Mill COAL HANDLING PLANTS

Aug 05, 2021The Ball mill pulveriser is basically horizontal cylindrical tube rotating at low speed on its axis, whose length is slightly more to its diameter. The inside of the Cylinder shell is fitted with heavy cast liners and is filled with cast or forged balls for grinding, to approximately 1/3 of the diameter. Raw coal to be ground is fed from the

Contact

THERMAL POWER PLANTS: COAL PULVERISING IN BOILERS

Aug 29, 2010A vertical spindle mill is also designed for pressurized and suction type requirements. Boiler designers use this type of mill for poor quality coal as this type of mill rejects foreign materials like stones and other high density materials. The power consumed by the mill per ton of coal ground is only two-thirds of the ball mills.

Contact

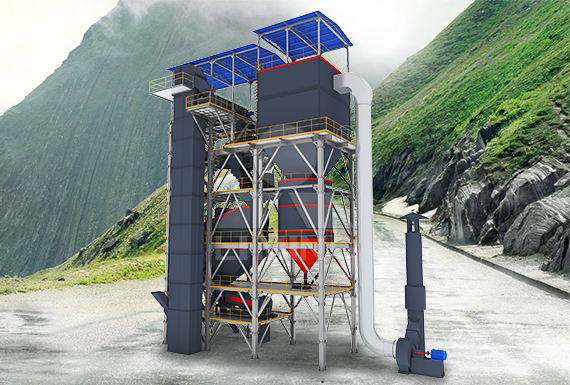

Products Khalsa Coal Pulverizing Plants

View Of Reheating Furnace Being Run On Khalsa Coal Pulverizer. 28inch coal pulverizer in a roll forging unit. billet being ejected from a reheating furnace. 42 inch x 2 No. Coal Pulverizers in a 20 TPH TMT mill. combustion blower (F.D Fan) billet reheating furnace. coal pulverizing plant with pre crusherelevator in a

Contact

coal pulverising mills ecritures-regards

Mar 01, 2017pulverising mill barytes nedervecht-kavels. About Bradley Pulverizer Company- pulverising mill barytes,Bradley began manufacturing the renowned single roll Griffin Mill in 1886 and, since then, has strived to supply our, (barite and bentonite), mineral fillers, clay, coal, utility (limestone grinding for SO2 removal), pulp and , chemical,.Joyal-Grinding Mills Used to Pulverize Barite for

Contact

Coal pulverising mills (Journal Article) ETDEWEB

Made available by U.S. Department of Energy Office of Scientific and Technical Information

Contact

Reliable pulverising all day, every day

The Essa Pulverising Mill range includes: Essa LM2 Pulverising Mill the geochemistry industry-standard, a reliable ring mill that prepares up to 1.8 kg of mineral ore for analysis; Essa LM5 Pulverising Mill used for pulverising larger sample size ores, the LM5 is particularly suited to the gold mining industry; Essa LM201 Pulverising Mill a top-of-the-range vibratory mill suited to

Contact

Col Pulverising Mills tcmzhao

Pulverizing Mills Each of the six units at Drax has ten pulverising fuel mills, each capable of pulverising 36 tonnes of coal per hour. Inside the mills, ten giant hollow steel balls, each 1.4 tonnes in weight and approximately 730 millimetres in diameter, crush the coal into a fine powder.

Contact