Produits phares

Manganese Ore Processing Mineral Processing

Apr 27, 2016Manganese Ore Concentration by Flotation The slime fraction of the ore overflowed by the hydraulic classifier and by the rod-mill spiral classifier is

Contact

manganese processing Britannica

Pure manganese is produced by hydrometallurgical and electrolytic processes, while ferromanganese and silicomanganese are produced by the smelting of ores in a blast furnace or, more commonly, in an electric furnace. The latter process, involving the

Contact

Manganese ore processing method

Weathered manganese oxide ore often contains a large amount of slime and fine ore, and the method of washing ore-selection is used in production. The net ore from the original ore after washing and removing the slime may be used as finished ore, and

Contact

Manganese Mining and Processing for Investors, Explained

The beginning of the Manganese ore processing involves a multistage crushing workflow. From there, the production of ferromanganese, the manganese ore is mixed with iron ore and carbon and then reduced either in a blast furnace or in an electric

Contact

How to Extract the Manganese Ore? Mining-pedia

Jul 15, 2019Adding lime milk to the filtrate, which can produce manganese hydroxide precipitation and then obtain solid manganese hydroxide after filtration process. This method is suitable for the manganese oxide ore with low grade and micro-grain. If you have any questions, please contact us by the following ways, and we will provide you with better help!

Contact

How to Extract the Manganese Ore? Mining-pedia

What Are the Processes and Equipment Used in the Manganese Processing? At present, the common manganese processing methods include washing, screening, gravity separation, strong magnetic separation and flotation, etc. Generally, manganese processing method adopts magnetic separation process mostly that has simple operation and strong adaptability.

Contact

Manganese Ore, Manganese Ore Processing Production

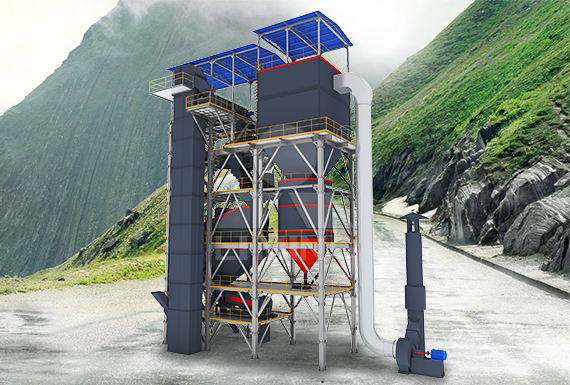

here are mainly three processes of manganese ore processing technology, includingstone crushing process, ore grinding process, and beneficiation process. During the stone crushing process, Three sections closed-circuit crushing

Contact

Manganese Mining and Extraction Manganese Mining

Manganese is a chemical element with the symbol Mn. It is a silvery white metal with a hard brittle structure that belongs to the group 7. Manganese are the fifth most abundant metal found in the crust of the earth that are distributed widely in many

Contact

The brief introduction of manganese ore sbmmineral

In the crushing section, we use our PE900x1200 jaw crusher to crush the manganese ore from 800 to 220 mm and then use the s series cone crusher S66" and S51"to crush the manganese ore from the jaw crusher into size 0-20mm. It is prepared for the beneficiation process. b.

Contact

how to process manganese ore a

The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry separation process with 1. Manganese ore processing method Weathered manganese oxide ore often contains a large amount of slime and fine ore, and the method of washing ore-selection is used in production.

Contact

How To Process Manganese Ore

Manufacturing process of manganese from its ore. Manganese processing Britannica,Manganese processing, preparation of the ore for use in various products. used manganese to improve the ability of steel produced by the Bessemer process to By the early 21st century, manganese production had expanded to several.Jan 26, 2014 The production of

Contact

How To Process Manganese

Manganese processing Britannica. Manganese processing, preparation of the ore for use in various products. Manganese (Mn) is a hard, silvery white metal with a melting point of 1,244 °C (2,271 °F). Ordinarily too brittle to be of structural value itself, it is an essential agent in steelmaking, in which it removes impurities such

Contact

Manganese Ore Processing Plant SolutionDesign JXSC Mining

Aug 06, 2021How to Build A Manganese Ore Processing Plant. 2021-08-06 by JXSC Mining. The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry tests. The magnetic separation process with 1 070 mm × 4 600 mm tank-type ore washing machine has a good effect.

Contact

How To Process Manganese

How To Process Manganese. 2015-02-10T02:02:29+00:00. Manganese Ore Processing Mineral Processing . 27/04/2016 Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10″ grizzly into a coarse ore bin The ore is

Contact

CN103014326A Sintering process of manganese ore powder

The process comprises the following steps of: adding water to mix manganese ore powder, a binding agent, fuel, a fluxing agent and return ore as mixed ore, wherein the binding agent is formed by mixing manganese salt and organic matter and counts for 0.6-3.0% of mass of the mixed ore, the fuel counts for 3.0-6.0% of mass of the mixed ore, the

Contact

How to Extract Manganese Ore? miningpedia

Feb 27, 2022The raw ore is washed to remove the slime, and some of the obtained net ore can be used as finished ore, and some need to be re-separated by jigging and shaking table. Ore washing overflow sometimes needs to be further recovered by gravity separation or strong magnetic separation. For some sedimentary primary manganese oxide ore, due to the

Contact

CN103667747A Process for producing manganese sulfate from

The invention discloses a process for producing manganese sulfate from low-grade manganese ores, which comprises the following steps: (1) roasting; (2) pulping; (3) sulfatizing, and performing coarse pressure filtration; (4) performing acid washing; (5) performing pressure filtration, rinsing, and further performing pressure filtration; and (6) performing refined pressure filtration on a

Contact

Manganese Wikipedia

A more progressive extraction process involves directly reducing manganese ore in a heap leach. This is done by percolating natural gas through the bottom of the heap; the natural gas provides the heat (needs to be at least 850 °C) and the reducing agent (carbon monoxide).

Contact

A Review of Low Grade Manganese Ore Upgradation Processes

Jul 29, 2019The ammonium salt roasting method is proposed to enrich and recover Mn from low grade ore of manganese carbonate. It included a process of

Contact

how to process manganese ore

how to process manganese ore Coal Surface Mining . how to process manganese ore Description : Manganese Ore Sorting Process And Equipment ore process crusher Manganese Ore Sorting Process And Equipment. Know More. Iron and manganese ore process Stone Crusher Machine Take your business to new heights with extraordinary products and

Contact

Mon How To Process Manganese Ore trinitytrade

Mon How To Process Manganese Ore . Process of mining manganese in pakistan. The Manganese Ore Processing Plant Crushing and Sampling of Manganese Rock The flowsheet incorporates a conventional multistage crushing plant with a grizzly or screen ahead of both the primary and secondary crushers The mine run ore is dumped through a 10 grizzly into a coarse ore bin.

Contact

The 7 Most Useful Manganese Ore Beneficiation Methods

May 15, 2022Why Producers Like It: ① Gravity separation method is suitable for manganese oxide ore with high density. It is the mainstream method of manganese ore beneficiation. ② The cost of the gravity separation process is much lower than that of the flotation process, and the

Contact

how to process manganese limestonegrinders

How To Process Manganese Ore. Manganese processing Britannica Manganese processing preparation of the ore for use in various products Manganese Mn is a hard silvery white metal with a melting point of 1 244 176 C 2 271 176 F Ordinarily too brittle to be of structural value itself it is an essential agent in steelmaking in which it removes impurities such ...

Contact

How To Process Manganese Ore

Manufacturing process of manganese from its ore. Manganese processing Britannica,Manganese processing, preparation of the ore for use in various products. used manganese to improve the ability of steel produced by the Bessemer process to By the early 21st century, manganese production had expanded to several.Jan 26, 2014 The production of

Contact

how is manganese ore processed posoda

Manganese Ore Processing. Manganese Ore Treatment SummaryThis flowsheet is designed to produce a maximum amount of the manganese in a coarse form which will be marketable without the further and high cost of nodulizing or sintering The gravity concentration sections do this Since

Contact

Manganese Ore an overview ScienceDirect Topics

Santanu Chakraborty, in Treatise on Process Metallurgy: Industrial Processes, 2014. 5.3.7 Manganese Ore. Manganese ore is required in iron making to control the manganese content of the hot metal in the desired range. Unlike other plants, where manganese ore lump is used directly in blast furnace, in VSP, it was proposed to use manganese ore fines in sinter productions.

Contact

Manganese Ore Processing Plant SolutionDesign JXSC Mining

Aug 06, 2021How to Build A Manganese Ore Processing Plant. 2021-08-06 by JXSC Mining. The process flow of the manganese ore processing plant is based on the results obtained from laboratory ore dressing tests and industry tests. The magnetic separation process with 1 070 mm × 4 600 mm tank-type ore washing machine has a good effect.

Contact

Manganese Mining and Extraction Manganese Mining Processing

Manganese is a chemical element with the symbol Mn. It is a silvery white metal with a hard brittle structure that belongs to the group 7. Manganese are the fifth most abundant metal found in the crust of the earth that are distributed widely in many countries.It is not found as a free element in nature, but present in the combination with iron.

Contact

how to process manganese ore

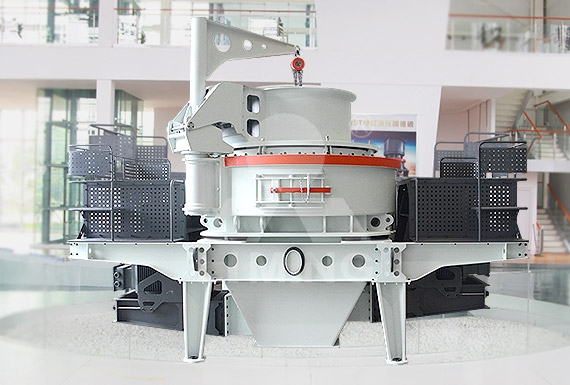

The following is a brief introduction to the ore dressing equipment of manganese ore mining process. 1 Gravity separation. Manganese gravity separation process flow: the raw ore enters the silo, is broken into a rough jaw crusher through a belt conveyor, and then enters the fine crusher for secondary crushing.

Contact

How To Process Manganese Ore

manganese ore magnetic process machine. Manganese ore processing plant consists of jaw crusher, hammer crusher, ball mill, classifier, flotation machine, concentrator, dryer mine feeder, hoist and conveyor. . manganese ore processing ste newstonight

Contact

Manganese Ore Beneficiation Manganese Ore Processing

Apr 03, 2019The purpose of manganese ore beneficiation is to remove the slime, separate stone and mineral manganese, enrich the low-grade ore, improve the ore grade, reduce the energy and reagent consumption of the smelting process from the source, and then reduce the amount of smelting waste. The methods of mineral manganese processing mainly include

Contact

A Review of Low Grade Manganese Ore Upgradation Processes

Jul 29, 2019The ammonium salt roasting method is proposed to enrich and recover Mn from low grade ore of manganese carbonate. It included a process of

Contact

Manganese Wikipedia

A more progressive extraction process involves directly reducing manganese ore in a heap leach. This is done by percolating natural gas through the bottom of the heap; the natural gas provides the heat (needs to be at least 850 °C) and the reducing agent (carbon monoxide).

Contact

The 7 Most Useful Manganese Ore Beneficiation Methods

May 15, 2022Why Producers Like It: ① Gravity separation method is suitable for manganese oxide ore with high density. It is the mainstream method of manganese ore beneficiation. ② The cost of the gravity separation process is much lower than that of the flotation process, and the

Contact

Process for the production of manganese dioxide, in particular for

DE-1592498-A1 chemical patent summary.

Contact

how to process manganese ore lottogeometry.de

5 Aug 2019 The next 300t of bagged manganese ore next to a new manganese ore The company is also in the process of signing additional sales/joint . Manganese Ore Indian Bureau of Mines indispensable input in making of iron all types of steels. manganese ore Industry in all its strata from Mines to manganese based alloy making processes.

Contact

how to process manganese vodafone-alumni

May 11, 2022Manganese Steel Frequency Asked Questions FAQ Know More. Manganese Steel Frequency Asked Questions FAQ,area to remain at visible red-heat for more than 2 or 3 minutes 1100-1200F approx at a time In the electric welding process, localized heat is dissipated fairly rapidly into the air and the bulk of the weldment,High-manganese steel under this treatment becomes ductile and

Contact