Produits phares

2022 new cone crusher aggregate size adjustment

Apr 18, 2022ChatNow: https://wa.me/8613621919955Contact: https://mpl-mineral/contact/Email: contact@mpl-mineralMore About 2022 new cone crusher aggrega...

Contact

How To Adjust A Cone Crusher mpl Heavy Industry

After repeated squeezing, shock and bending, the material crushing to the required particle size, the lower part of the discharge. How to Adjust a Cone Crusher: 1, the oil temperature is too high. Reason: bad oil quality; insufficient oil; bearing damage. If you need any help of how to adjust a cone crusher, please contact us directly. We

Contact

Size reduction control in cone crushers ScienceDirect

Nov 01, 2021Manipulated variables, MVs There are three possible MVs that can be used to regulate the cone crusher size reduction: 1. Closed side setting ( CSS ), governing the volumetric capacity of a crusher 2. Eccentric speed ( ω es ), governing the number and intensity of crushing events 3.

Contact

A Detailed Overview of Cone Crushers and What You

Jun 03, 2020A first-stage crusher, such as an impact or jaw crusher is used to break raw material down to a size that the cone crusher can accommodate. Cone crushers are typically looked at as a secondary or tertiary stage of crushing. But, they can also act as the first stage provided the material is small enough to fit through the feed opening.

Contact

12 tips to maximize cone crusher productivity Metso

Feb 11, 2020A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper “loaded bearing alignment”. An optimal power range is to operate between 75%-95%. Operating a crusher above 110% rated power can cause premature crusher failure.

Contact

Selecting crushing chambers for cone crusher Metso

Apr 07, 2020This is discussed in more detail in the 12 tips to maximize cone crusher productivity blog post. Summarizing, larger setting → product size increases, capacity increases, power draw decreases. Example: The HP crusher chamber selection table shows the minimum opening settings. However, the presented settings are provided as a guide only.

Contact

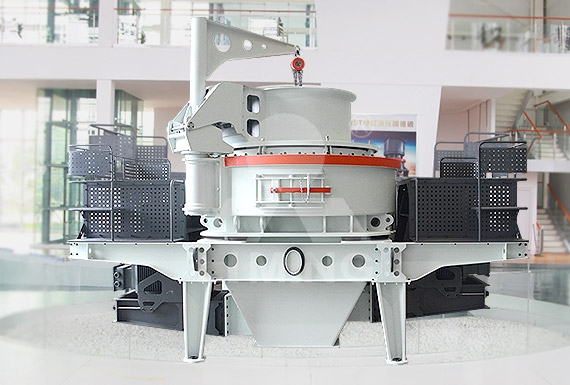

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Contact

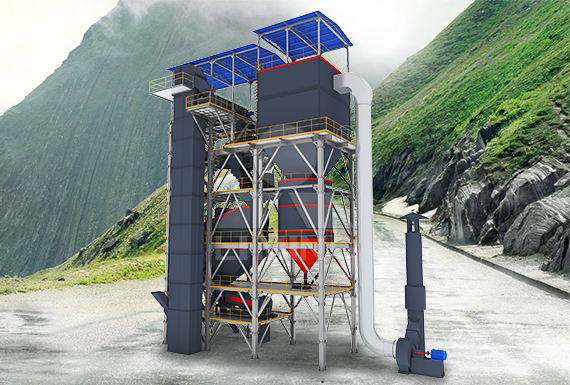

How to Control the Discharge Size in Crushing Stone and

Mar 12, 2022The main objectives of particle size control are: firstly, to make the configuration and operation of the crushing machinery layer reasonable, secondly, to reduce the proportion of needle-like and flake aggregate in finished products, thirdly, to adjust the proportion of each particle size of the finished aggregate.

Contact

Crusher Close Side Settings Mineral Processing

Jan 17, 2016The maximum feed size is approximately 8 0% of the feed opening. Open side setting (OSS) The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies. Closed side setting (CSS)

Contact

Cone Crusher Aggregate Size Adjustment

Cone Crusher Aggregate Size Adjustment. mpl cone crusher aggregate size adjustment cone crusher agregate size adjustment,at its heart is the automax cone crusher with hydraulic setting, learn more get more info crush size agregate birlafinance aggregate crusher 2013 6 3 cone crusherne crusher cone crusher vibrating feeder introduction it

Contact

cone crusher agregate size adjustment sremachineries

Cone Crushers Mineral Processing Metallurgy. Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble critical size buildup problem Normally heavy duty shorthead crushers are employed to crush pebbles Power and crusher cavity level are the key variables for monitoring and controlling the crusher operation

Contact

Cone Crusher Agregate Size Adjustment Stone Crusher Machine

Cone Crusher Agregate Size Adjustment Stone Crusher Machine. Symons Cone Crusher Capacity: 80TPH-610TPH Feeding size: 80mm-300mm +86 [email protected] Inquire Now JXSC provides a high-quality rock crusher cone machine, like the brands of Mesto and . stone shaping in building aggregate, highway, asphalt concrete and cement

Contact

cone crusherzhengzhoucone crushing aggregate size

Stone Cone Crusher Agregate Size Adjustment. Stone Cone Crusher Agregate Size Adjustment. Jul 28, 2020 In the sand and stone aggregate market, stones or sand the customers need to have a certain standard particle size, for example gravel is divided into 5-10 mm, 10-20 mm, 16-31.5 mm, sand is divided into coarse sand average particle size of 0.5 mm or more, medium sand average particle size

Contact

cone crusher aggregate size adjustment

3 Types Of Discharge Adjustment Devices For Cone Crushers. 2021-6-15 Cone crusher is one of the mainstream crushing equipment in mining industry. It is mainly used for medium or fine crushing for various kinds of raw materials. The output size of cone crusher is determined by the distance between mantle and concave.

Contact

Cone Crusher Agregate Size Adjustment

Raptor174; Cone Crushers Smart Cone Crushers With. product also make the R450 an excellent tertiary crusher for aggregate asphalt or concrete products. Ease of installation The Raptor Cone Crushers R250 R350 and R450 are easy to install. The unit crusher lubricant and hydraulic skids arrives onsite at your projects location on a. Read More

Contact

stone cone crusher agregate size adjustment

CME cone crusher aggregate size adjustment Maximize your cone crusher productivity : Pit Quarry Apr 28, 2017 An example of the effect that crusher setting has on the product gradation is as follows: If the target crusher setting is 3/8 in. (10 mm) but the setting is not checked and it wears open to 1/2 in. (13 mm), then the end result is a

Contact

cone crusher agregate size adjustment

CME cone crusher aggregate size adjustment Maximize your cone crusher productivity Pit Quarry Apr 28 2017 An example of the effect that crusher setting has on the product gradation is as follows If the target crusher setting is 3/8 in 10 mm but the setting is not checked and it wears open to 1/2 in 13 mm then the end result is a...

Contact

cone crusher aggregate size adjustment

European Type Jaw Crusher is a new crushing machine, the jaw crusher manufacturer, after the release of traditional jaw crusher. This jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers. Input Size: 0-930mm Capacity: 12-650TPH

Contact

Selecting crushing chambers for cone crusher Metso Outotec

Apr 07, 2020CSS should be close to the required product. The setting is too small if the adjustment ring is moving on the main frame. This is discussed in more detail in the 12 tips to maximize cone crusher productivity blog post. Summarizing, larger setting → product size increases, capacity increases, power draw decreases.

Contact

Cone Crusher Aggregate Size Adjustment In Inside China

> Cone Crusher > Cone Crusher Aggregate Size Adjustment In Inside China; Aug 23 2021 used hp300 portable rear discharge cone plant 2003 hp 300 cone 300hp 1800rpm crusher duty cone motor hydraulic adjust underload 80. learn more. How To Control The Discharge Size In Crushing Stone.

Contact

Cone Crushers McLanahan

FeaturesBenefits. A Cone Crusher will deliver a 4:1 to 6:1 reduction ratio. As we set the closed side setting tighter to create a finer output, we also reduce the volume or throughput capacity of the machine. Generally speaking, multiplying the closed side setting by two is a good guide to the top size of the gradation exiting the machine.

Contact

stone cone crusher agregate size adjustment

Mar 27, 2021 In the sand and stone aggregate market, stones or sand the customers need to have a certain standard particle size, for example: gravel is divided into 5-10 mm, 10-20 mm, 16-31.5 mm, sand is divided into coarse sand (average particle size of 0.5 mm or more), medium sand (average particle size of 0.35-0.5 mm), fine sand (average particle size of

Contact

cone crusher aggregate size adjustment

The material Cone crusher: Adjustment of the cone crusher, see page 188, acc. to ; Real-Time Optimization of Cone Crushers Chalmers Research. 8 Dec 2010 Cone crushers are used in the mineral, mining, and aggregate industry for speed and on-line CSS adjustment based on information from the process.

Contact

Cone Crusher Aggregate Size Adjustment

Cone Crusher Aggregate Size Adjustment. mpl cone crusher aggregate size adjustment cone crusher agregate size adjustment,at its heart is the automax cone crusher with hydraulic setting, learn more get more info crush size agregate birlafinance aggregate crusher 2013 6 3 cone crusherne crusher cone crusher vibrating feeder introduction it

Contact

cone crusher agregate size adjustment sremachineries

Cone Crushers Mineral Processing Metallurgy. Cone crushers are used in AG and SAG grinding circuits to increase tonnage by effectively dealing with any pebble critical size buildup problem Normally heavy duty shorthead crushers are employed to crush pebbles Power and crusher cavity level are the key variables for monitoring and controlling the crusher operation

Contact

stone cone crusher agregate size adjustment

Mar 27, 2021 In the sand and stone aggregate market, stones or sand the customers need to have a certain standard particle size, for example: gravel is divided into 5-10 mm, 10-20 mm, 16-31.5 mm, sand is divided into coarse sand (average particle size of 0.5 mm or more), medium sand (average particle size of 0.35-0.5 mm), fine sand (average particle size of

Contact

cone crusherzhengzhoucone crushing aggregate size

Stone Cone Crusher Agregate Size Adjustment. Stone Cone Crusher Agregate Size Adjustment. Jul 28, 2020 In the sand and stone aggregate market, stones or sand the customers need to have a certain standard particle size, for example gravel is divided into 5-10 mm, 10-20 mm, 16-31.5 mm, sand is divided into coarse sand average particle size of 0.5 mm or more, medium sand average particle size

Contact

CS cone crusher agregate size adjustment

Cone Crusher Size Adjustment Cone Crusher 2020 08 01 Cone crusher agregate size adjustmentcone crusher agregate size adjustmentC1550 cone crusher transdiesel c1550 cone crusher tm cone scm1300 cone chamber 1300mm 51 head diameter medium coarse concave max feed size 220mm a quality aggregate fully hydraulic css adjustment with electronic

Contact

stone cone crusher agregate size adjustment

As we may know that there are several differnt types of cone crushers, like spring cone crusher, single cylinder cone crusher, multiple cylinder cone crusher and so on. which are designed for crushing over 120 kinds of rocks, such as limestone, granite, quartz, basalt, river stone, gold ore, iron ore, coal, gravel, aggregate etc. Different

Contact

Cone Crusher Aggregate Size Adjustment In Inside China

> Cone Crusher > Cone Crusher Aggregate Size Adjustment In Inside China; Aug 23 2021 used hp300 portable rear discharge cone plant 2003 hp 300 cone 300hp 1800rpm crusher duty cone motor hydraulic adjust underload 80. learn more. How To Control The Discharge Size In Crushing Stone.

Contact

cone crusher aggregate size adjustment

European Type Jaw Crusher is a new crushing machine, the jaw crusher manufacturer, after the release of traditional jaw crusher. This jaw crusher is a perfect combination of modern science and technology and the production practice, which can better satisfy the automatic production demands of vast customers. Input Size: 0-930mm Capacity: 12-650TPH

Contact

12 tips to maximize cone crusher productivity Metso Outotec

Feb 11, 2020Avoid trickle feeding the crusher. Try not to trickle feed a cone crusher. In addition to causing poor cone crusher productivity and product shape, trickle feeding has an impact on bearing alignment within said crusher. A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to

Contact

Crusher Close Side Settings Mineral ProcessingMetallurgy

Jan 17, 2016The maximum feed size is approximately 8 0% of the feed opening. The open side setting is measured when the crusher is at rest. The setting is measured either top to top, or bottom to top, depending on the tooth profile of the jaw dies. The closed side setting can be calculated by deducting the stroke from the OSS.

Contact

Stonecone Crusher Agregate Size Adjustment

Mar 27 2021 In the sand and stone aggregate market stones or sand the customers need to have a certain standard particle size for example gravel is divided into 5-10 mm 10-20 mm 16-31.5 mm sand is divided into coarse sand average particle size of 0.5 mm or more medium sand average particle size of 0.35-0.5 mm fine sand average particle size of .

Contact

Cone Crusher Agregate Size Adjustment factjeugdnoord

Cone Crusher Agregate Size Adjustment. Simons 5 1 2 cone crusher technical information CS 5 1 2 cone crusher technical information productss a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any size-reduction requirements including, CS 5 1 2 cone crusher technical information, quarry, aggregate.

Contact

stone cone crusher agregate size adjustment

Cone crusher agregate size adjustment how adjust a cone crusherone crushers are used in aggregate and mining industriese equipment also can adjust the size ow to adjust cone crushers grinding mill one crusher adjust henan mining heavy machinery coltdthe raptor xl400 cone crusher mainframe, crusher clamp ring.

Contact

How to Control the Discharge Size in Crushing Stone and Sand?

Mar 12, 2022In the sand and stone aggregate market, stones or sand the customers need to have a certain standard particle size, for example: gravel is divided into 5-10 mm, 10-20 mm, 16-31.5 mm, sand is divided into coarse sand (average particle size of 0.5 mm or more), medium sand (average particle size of 0.35-0.5 mm), fine sand (average particle size of

Contact