Produits phares

Mineral and Technological Features of Magnetite

Mineralogical studies have established that the main iron-bearing mineral is hematite, which contains 69.02 to 70.35% of iron distributed in the ore. Magnetite and hydrogoethite account for 16.71-17.74 and 8.04-10.50% of the component, respectively; the proportion of iron distributed in gangue minerals and finely dispersed iron hydroxides is

Contact

Mineral and Technological Features of

Apr 06, 2021It has been found that the main iron-bearing mineral is hematite, which contains 69.02 to 70.35% of iron distributed in the ore. Magnetite and hydrogoethite account for 16.71–17.74 and 8.04–10.50% of the component, respectively; the proportion of iron distributed in gangue minerals and finely dispersed iron hydroxides is very insignificant.

Contact

Iron Ores (Hematite and Magnetite) GeeksforGeeks

Nov 07, 2021Magnetite is a ferromagnetic mineral, whereas hematite is a paramagnetic mineral. As a result, these materials can be separated using a low-intensity magnetic separation method. An induced roll magnetic separator is used in this application. The magnetite and hematite mixture is fed to the separator from the top in this method.

Contact

Mineral and Technological Features of

Mar 24, 2021Iron oxides are naturally occurring mineral compounds existing in three well-known polymorphic forms, including hematite (α-Fe 2 O 3 ), maghemite (γ-Fe 2

Contact

Binding effects in hematite and magnetite concentrates

May 08, 2011The facility, ‘Plant F’, processes hematite 6 months of the year; magnetite is pelletized the other 6 months. Smaller doses of bentonite are believed to be required for hematite pellets compared to magnetite pellets. Understanding why this occurs is important economically.

Contact

Processing of Magnetite Iron Ores–Comparing Grinding

The results of a theoretical option study for high capacity processing of a hard, fine-grained silica-rich magnetite ore is presented in this , with the emphasis on comminution circuit...

Contact

Difference Between Magnetite and Hematite Pediaa.Com

Jan 31, 2018Magnetite and hematite are two forms of iron ores from which iron can be extracted. Magnetite contains iron in the form of Fe 3 O 4. Hematite contains iron in the form of Fe 2 O 3. The main difference between magnetite and hematite is that magnetite is ferromagnetic whereas hematite is paramagnetic. Key Areas Covered 1. What is Magnetite

Contact

Magnetite Common Minerals

If enough magnetite is present to give the sample a magnetic character, the magnetism can mask the presence of these other minerals or lead to their misidentification. Hematite: Hematite is economically the most important iron ore, since it is more abundant than magnetite.

Contact

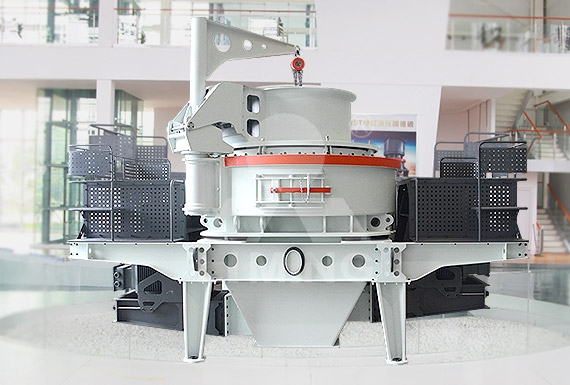

Magnetite ProcessingExtraction Jig

Jan 12, 2017Jig Magnetite ProcessingExtraction set of six crushers, set to ¼-inch. These are of the Blake multiple- jaw pattern, having three jaws. The product from these third crushers is again screened through a double revolving screen, having holes ¼-inch in diameter.

Contact

Iron Ores (Hematite and Magnetite) GeeksforGeeks

Nov 09, 2021An ore is a mineral deposit that contains a metal that can be extracted using existing technological methods. Iron can be extracted from two types of iron ores: Magnetite and hematite. Magnetite is composed of iron in the form of Fe 3 O 4. Hematite is a mineral that contains iron in the form of Fe 2 O 3.

Contact

Hematite vs Magnetite: What Are They, And What’s The Difference?

How The Two Can Be Confused. Hematite is an iron oxide with the chemical formula Fe2O3; magnetite is also an iron oxide but with the chemical formula Fe3O4. Another important difference between hematite and magnetite is that hematite appears in a variety of colors, but magnetite is only black in color. Hematite makes a rust or blood-red colored

Contact

Binding effects in hematite and magnetite concentrates

May 08, 2011The magnetite concentrate used was provided by a taconite processing plant, Plant D. The concentrate contained ~ 8.5% moisture and was 80% passing 49 μm; specific surface area (Blaine) was 2250 cm 2 /g. The concentrate was divided into approximately 2.5 kg samples using a riffle splitter and sealed in plastic bags to preserve moisture content.The XRD spectrum of the magnetite sample

Contact

Difference Between Magnetite and Hematite Pediaa.Com

Jan 31, 2018Mineral Streak. Magnetite: The streak of magnetite is black. Hematite: The streak of hematite is red to reddish brown. Conclusion. Magnetite and hematite are important minerals that can be used as sources for extraction of iron. The main difference between magnetite and hematite is that magnetite is ferromagnetic whereas hematite is

Contact

Processing of Magnetite Iron Ores–Comparing Grinding Options

An option study for a 10 Mt/a ore processing plant for a. consistently hard, fine-grained silica-rich magnetite ore was. carried out, with the emphasis on comminution circuit options. A. capacity

Contact

Types of Iron Ore: Hematite vs. Magnetite_SMM Shanghai Non

Sep 06, 2013The deposit was discovered in 1844 and ore was first mined there in 1848, as per the State of Michigan’s website. Among the four types of iron ore deposits found in this area are magnetite and hematite ore. In Minnesota, magnetite iron ore is mined mainly in the Mesabi iron range, one of the four ranges that make up the Iron Range of Minnesota.

Contact

Replacement of magnetite by hematite in hydrothermal

Jan 01, 2022The replacement of magnetite by hematite is commonly observed in various geologic systems. In contrast to the formation of hematite by a solid-state oxidation, numerous experimental results have demonstrated that it can also occur by a redox-independent dissolution-reprecipitation reaction. Mineral stability relations in a skarn system are

Contact

Eco-efficient and cost-effective process design for magnetite iron

Feb 24, 2015Energy and greenhouse gas impacts of mining and mineral processing operations (source: Norgate, T y Haque, N. 2010). The majority of steel production is supported by iron ore sourced from high-grade hematite deposits, although a significant fraction comes from magnetite deposits. case specific and the intention of this stone is to show the

Contact

Hematite Processing

It usually accretes with magnetite ore. In China, hematite as a major mineral in quite a number of iron ore. The main origins of iron ore are Australia, Brazil, India, Canada, Russia, etc. The density of hematite is 4.8-5.3t/m³, hardness is 5.5-6.5, loose density is 2.5-3.0t/m³.

Contact

Iron Ore Processing Prominer (Shanghai) Mining Technology Co

There are many types of iron ore, but mainly magnetite (Fe3O4) and hematite (Fe2O3) are used for iron production because magnetite and hematite have higher content of iron and easy to be upgraded to high grade for steel factories. Submit your requirement below for mineral processing proposal! Please contact whatsapp number via +86

Contact

Hematite and magnetite processing Manufacturer Of High

20181122Hematite Processing The molecular formula of hematite is Fe2O3; it belongs to weak magnetite iron ore content It usually accretes with magnetite ore In China, hematite as a major mineral in quite a number of iron ore The main origins of iron ore are Australia, Brazil, India, Canada, Russia, etc

Contact

(PDF) Recovery of Magnetite from Leached Laterite-residue by

in the mineral processing especially in the concentration of Therefore, the laterite ore can be an alternative of iron re- iron ore. Mineralogy of the sample duction of hematite to magnetite with time for 30 mol% CO that is reported in the previous study shows that impurities reduction treatment, which was calculated from the weight such

Contact

Magnetite: The mineral Magnetite information and pictures

The Mineral magnetite. Magnetite is best known for its property of being strongly attracted to magnet s. Some forms of Magnetite from specific localities are in fact themselves magnets. Commonly known as Lodestone, this magnetic form of Magnetite is the only mineral that is a natural magnet. Due to the magnetism of Lodestone, small iron

Contact

hemetite crushing restaurant-mezzee.fr

Feb 03, 2018Projects Crushing. 2014 (May 2012 Feb 2014) Karara Iron Ore Crushing of Magnetite Iron Ore. 2014 (Sept 2011 Aug 2014) Brierty Ltd / Karara Iron Ore Mine crushing 1 Mtpa Hematite Iron Ore over 4 years with capacity to ramp up to 3.6 Mtpa at times. 2010 2011 Karara Iron Ore Trial crushing of DSO Hematite

Contact

Hematite and magnetite processing Manufacturer Of High

20181122Hematite Processing The molecular formula of hematite is Fe2O3; it belongs to weak magnetite iron ore content It usually accretes with magnetite ore In China, hematite as a major mineral in quite a number of iron ore The main origins of iron ore are Australia, Brazil, India, Canada, Russia, etc

Contact

Hematite And Magnetite Mineral Processing

Beneficiation of hematite iron ore. also known as red hematite ore of its chemical formula is fe2o3, which is a weakly magnetic iron minerals, magnetite floatability than good, one of the main raw material is iron. the main mineral processing technology have reelection, and strong magnetic separation or flotation process and use a variety of.

Contact

hematite and magnetite mineral processing

May 24, 2019 Hematite magnetic separation process mostly adopts weak-strong magnetic separation process, which is used to treat magnetite-hematite mixed ore. Mineral processing index: The selected grade was 23.15%, the concentrate grade was 65.95% and the tailings grade was 10.05%, which greatly improveed the technical index of mineral

Contact

Difference Between Magnetite and Hematite Pediaa.Com

Jan 31, 2018Mineral Streak. Magnetite: The streak of magnetite is black. Hematite: The streak of hematite is red to reddish brown. Conclusion. Magnetite and hematite are important minerals that can be used as sources for extraction of iron. The main difference between magnetite and hematite is that magnetite is ferromagnetic whereas hematite is

Contact

The transformation of magnetite to hematite and its

The hard magnetite behaves in a brittle manner with a very limited operation of slip along the main crystallographic planes. The microfracturing creates an easy path for oxidation and transformation of magnetite. The newly formed hematite grains behave in a ductile manner and form a matrix of strongly oriented crystals.

Contact

Magnetite: The mineral Magnetite information and pictures

The Mineral magnetite. Magnetite is best known for its property of being strongly attracted to magnet s. Some forms of Magnetite from specific localities are in fact themselves magnets. Commonly known as Lodestone, this magnetic form of Magnetite is the only mineral that is a natural magnet. Due to the magnetism of Lodestone, small iron

Contact

The Study of Pelletizing of Mixed Hematite and Magnetite

2.2.1. Preparation of magnetite and hematite mix A set of trials has been designed with four types of mixtures in order to know the properties of pellets produced with hematite and magnetite concentrates. The mixing ratios of magnetite and hematite used in the

Contact

IDENTIFICATION OF MAGNETIC MINERALS BY SCANNING

between magnetite and hematite (Just et al., 2004). This method is also widely applied in nanotechnology studies as e.g. shown by Yellen et al. (2004). A ferrofluid is a stable colloidal suspension of magnetite/maghemite particles that range in size from 11

Contact

Magnetite Wikipedia

Magnetite is a mineral and one of the main iron ores, with the chemical formula Fe 2+ Fe 3+ 2 O 4.It is one of the oxides of iron, and is ferrimagnetic; it is attracted to a magnet and can be magnetized to become a permanent magnet itself. With the exception of extremely rare native iron deposits, it is the most magnetic of all the naturally occurring minerals on Earth.

Contact

Metallogeny of the Hunjiang basin, northeastern North China Craton

2 天前A Mo processing facility was constructed between 2008 and 2014. The orebody comprises massive magnetite and hematite replacing Proterozoic marble of the Qingbaikou Group (Fig Magnetite is the predominant ore mineral and is massive to disseminated, replacing the host marble. Hematite is less common but can be intergrown with magnetite

Contact

Types of Iron Ore: Hematite vs. Magnetite MineListings

Jan 04, 2016That makes the iron extraction process much less costly and time consuming. In addition, hematite ore only goes through one stage of screening and crushing, while magnetite ore has an additional round of processing. Types of iron ore: Magnetite. With the chemical formula Fe3O4, magnetite ore has much lower iron content than hematite ore.

Contact

Effect of magnetite on mineral phase formation in sintering process

To clarify the effects of magnetite on mineral phases formation, sintering experiments using hematite and magnetite reagent were carried out. atmosphere at 1 250°C and 1 350°C respectively. The results were analyzed by microscopic observation and image processing. Under both oxidizing and reducing atmosphere, the shapes of each phase

Contact

hematite and magnetite processing kitchenempire

hematite and magnetite processing. Jul 10 2017 Gaviria et al 2007 studied hematite to magnetite reduction by monitoring it with the help of Mössbauer spectroscopy and XRD This process includes isothermal heating of hematite in a flow of H 2 –Ar mixture at temperatures between 260 and 360 °C The hematite fully transformed to magnetite after 40 min at 320 °C...We are a professional

Contact

Magnetite ProcessingExtraction Jig

Jan 12, 2017All the material which passes through the ¼-inch holes goes to the jigs without further sizing. The ore is crushed dry, and goes to the jigs in that state. The machine, as shown in the accompanying drawings, may be divided into four essential parts: 1.

Contact