Produits phares

Cone Crusher an overview ScienceDirect Topics

The Standard cone crushers are for normal use. The Short Head cone crushers are designed for tertiary or quaternary crushing where finer product is required. These

Contact

Cone crusher basics in 4 minutes SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work and how they can make your mine or quarry more productive. Elsewhere on the site you can find detailed information about all aspects of crushing and screening, but to make sense of these it helps to understand the basics of cone crushing.

Contact

A Detailed Overview of Cone Crushers and What You

Jun 03, 2020A cone crusher has two sides: an open side and a closed side. As the material crushes, the particles that are small enough to fit through the open side fall

Contact

Cone Crusher an overview ScienceDirect Topics

The concrete C&D waste recycling process of “impact crusher + cone crusher + hoop-roller grinder” is also capable of handling brick waste. In general, the secondary crushing using the cone crusher in this process with an enclosed crusher is a process of multicrushing, and the water content of waste will become an important affecting factor.

Contact

A Detailed Overview of Cone Crushers and What

Jun 03, 2020Plus, cone crushers can be controlled remotely, helping to reduce work site dangers in the process. Cone Crusher vs. Jaw Crusher: Key Differences. While companies use both machines for crushing raw materials, several vital

Contact

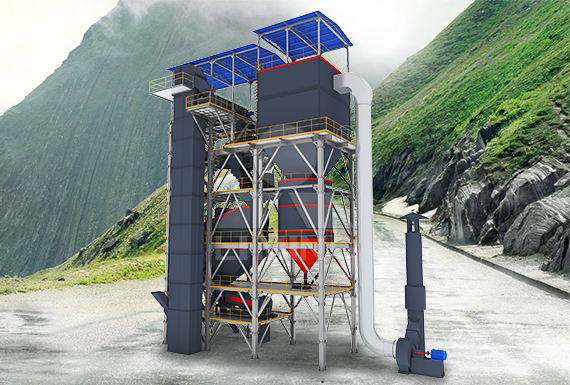

Cone Crushers — SRP

cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize crusher performance and productivity.

Contact

Cone Crusher Mineral ProcessingMetallurgy

Apr 19, 2018The cone crusher is usually set to give a 3/8-in. or ½-in. product when discharging to ball mills. Table 9 gives particulars of the different sizes of crushers. The capacity figures are based on material weighing 100 lb. per cubic foot and must be

Contact

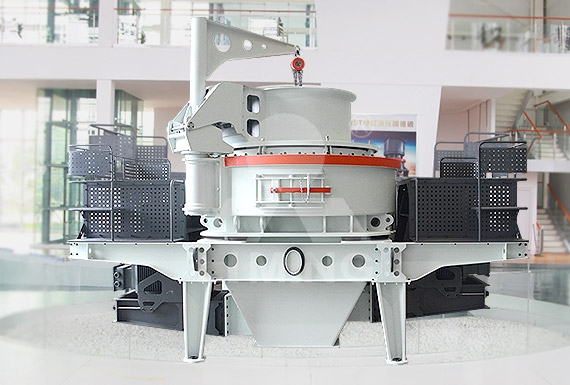

Cone Crusher, Stone Rock Crusher Machine JXSC

Cone Crusher. +8613879771862. sales@jxscmining. Inquire Now. Cone crusher is a compression type of rock size reducing machine that crushes rockstone material by the physical compression force forming by the fixed steel and the moving steel.

Contact

Cone Crusher 1000SR

Cone Crusher. The ® 1000SR mobile cone crusher is built around the successful 1000 Maxtrak model and features a re-circulating conveyor and a double-deck post-screen to provide a complete crushing and screening process on a single

Contact

Used Cone-crushers For Sale amking

UNUSED SANDVIK CH880 STD Cone Crusher. Inventory ID: 3C-OT04. UNUSED SANDVIK CH880 STD Cone Crusher (4 Units) Tertiary Crusher, Tertiary Medium Liner. Manufacturer: SANDVIK. View Details. Size. Model. CH880. Manufacturer.

Contact

4 Dust-proof Ways of Cone Crushers Sandrock Mining

Sep 03, 2021The 2 cone crushers process 490t more ore per month and 4410t more ore per year, with an annual benefit of more than USD 3,000. Save lubricating oil. After changing the dust-proof method, the oil change phenomenon caused by water in the lubricating oil station is solved, and 1620kg of lubricating oil can be saved every year, saving more than

Contact

cone crushers optimization

cone crusher chamber optimization using multiple. Oct 01, 2009 The purpose of chamber geometry optimization is to design the geometry of the concave chamber surfaces given that the key parameters, including rotational speed n, eccentric angle γ, height of pivot

Contact

Cone Crusher Process Flow Diagram Processing Line(SHIBANG)

Jun 22, 2022WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co...

Contact

Keestrack H6e Cone Crusher

Capacity up to 395 tonnes / hour. Hopper 8 m³ (10 yard³) Other configurations possible with different crushing chambers. Diesel / electric drive. 2 speed track drive. Optional 3-deck screen: Top: 4.640 mm x 1.800 mm, Middle and bottom 4.500 mm x 1.800 mm (14’9″ x 5’10”) Effective screen area 8,1 m² on each deck, with return conveyor.

Contact

P&Q University Lesson 7- CrushingSecondary Breaking Pit

Sep 02, 2019Secondary impact crushers and cone crushers are used to further process primary-crushed aggregate, and can be operated with or without attached screening units. These crushers can be used as either secondary or tertiary crushers depending on the application. When interlinked to other mobile units such as a primary or screen, complicated

Contact

Jaw Crusher VS Cone Crusher Advantages and Disadvantages

For example, Compound Cone crusher configured in the back process of jaw crusher. The jaw crusher equipment broken too large discharge will plug the cone crusher feed mouth. Resulting crusher plant can not run smoothly. For the matching of jaw crusher and cone crusher. It is necessary to compare the particle size range of the two materials.

Contact

What is the difference between Impact Crusher and Cone ZENITH Crusher

Dec 07, 2021The i. In general, impact crushers both vertical shaft (VSI) and horizontal shaft (HSI), the main difference from the cone crusher is the type of crushing force. The impact crusher crush by material impacting another object. The cone crusher uses compression crushing to squeeze or compress the material between the two crushing surfaces.

Contact

Cone crusher basics in 4 minutes SRP

The CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher. Sampling is a vital part of the crushing process, to ensure that you know the size distribution of the feed.

Contact

Cone Crushers MEKA CrushingScreening Plants

Designed especially for the hardest material types, cone crushers are one of the best choices for crushing river gravel, basalt and granite, along with abrasive materials in the mining industry like iron, chrome, magnesite and copper ores. The robust design and

Contact

Cone Crusher JXSC Machine

Cone Crusher is mainly used as a primary stone crusher machine in the mining plant, aggregate processing plants. JXSC rock crusher CE, SGS certified. and mobile cone crusher (track, wheeled); liner adjustment to process larger or finer-sized material;

Contact

Cone Crushers Moore Watson Ltd

Cone crusher capacity charts are developed for use as an application tool to properly utilize the MHP crusher's capabilities. The capacity figures shown apply to material weighing 100 pounds per cubic foot or 1600 kg per cubic meter. The crusher is one component of the circuit. As such, its performance is in part dependent on the proper

Contact

Cone Crusher 1000SR

Cone Crusher. The ® 1000SR mobile cone crusher is built around the successful 1000 Maxtrak model and features a re-circulating conveyor and a double-deck post-screen to provide a complete crushing and screening process on a single

Contact

Cone crusher parts Metso Outotec

Our cone crusher parts are designed to the same specifications and standards as our cone crusher equipment, ensuring equipment compatibility for reliable and safe operation. Carefully produced at our own foundries. We have complete control over

Contact

4 Dust-proof Ways of Cone Crushers Sandrock Mining

Sep 03, 2021The 2 cone crushers process 490t more ore per month and 4410t more ore per year, with an annual benefit of more than USD 3,000. Save lubricating oil. After changing the dust-proof method, the oil change phenomenon caused by water in the lubricating oil station is solved, and 1620kg of lubricating oil can be saved every year, saving more than

Contact

Jaw Crusher VS Cone Crusher Advantages and

For example, Compound Cone crusher configured in the back process of jaw crusher. The jaw crusher equipment broken too large discharge will plug the cone crusher feed mouth. Resulting crusher plant can not run smoothly. For the matching of jaw

Contact

(PDF) Cone Crusher Performance ResearchGate

May 13, 2015existing crusher equipment, such as jaw and cone crushers, the interdependency matrix will be different from triangular. This is the fact behind the complexity of the crushing process.

Contact

Automation Advances Productivity of Cone Crushers

Sep 15, 2020“The main advantage of cone crushers is the ability to process big tonnages at a very efficient operational cost,” said Vincent Celsi, vice president of crushers for Metso Outotec. How to Select a Cone Crusher. When it comes to selecting the type of crusher, there aren’t any hard rules to follow. One consideration is how often you plan to

Contact

cone crushers optimization

cone crusher chamber optimization using multiple. Oct 01, 2009 The purpose of chamber geometry optimization is to design the geometry of the concave chamber surfaces given that the key parameters, including rotational speed n, eccentric angle γ, height of pivot

Contact

Trio® cone crushers The Weir Group

Dec 17, 2020The Trio ® TP fixed shaft (or pedestal) cone crusher can utilise substantially more horsepower, with a bigger eccentric throw and a higher pivot point to deliver throughput as high as 1,000 MTPH. The TP series also benefits from higher percentages of interparticle crushing which enables it to produce a finer product curve compared to TC style

Contact

Cone Crusher Process Flow Diagram Processing Line(SHIBANG)

WhatsApp: https://wa.me/8613621919955?text=Pls+send+us+this+message+first%2C+then+we+will+arrange+for+the+right+sales+engineer+to+serve+you%21+Your+Unique+Co...

Contact

US440E Cone crusher SRP

US440E mobile cone crusher is a highly efficient electrically powered, track-mounted complete process machine with a cone crusher and screen onboard. It has been designed to meet the demands of quarry operators, construction companies, mining companies or contractors working with highly abrasive materials, and it is the ideal solution for your secondary and tertiary applications.

Contact